1.Project background

Open-pit coal yards, ore stockyards generate significant dust pollution during stacking and loading and unloading operations, especially on windy days, leading to pollution in surrounding areas and significant material losses. With increasingly strict national air pollution control policies and the launch of initiatives like “Blue Sky Defense,” open-pit coal yards, ore stockyards in ports, power plants, and other areas face immense environmental pressure. To address this, efforts have focused on wind control and dust reduction technology, starting from wind control. Shangfeng’s developed wind control and dust suppression wall technology fully utilizes the principles of aerodynamics to control wind and effectively mitigate dust pollution. This technology has been listed in the National Environmental Protection Practical Technology Catalog and included in the Ministry of Science and Technology’s national technology support program for the promotion of wind control and dust reduction technology nationwide.

2、 Governance plan

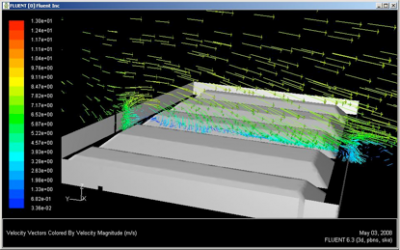

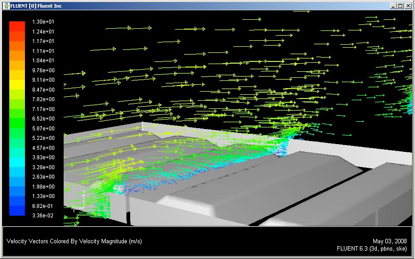

Based on the height of material piles and the area of the stockyard, wind control walls are installed in the dominant wind direction. When the wind passes through these walls, phenomena such as separation and attachment occur behind them, creating upper and lower interfering airflow that reduces the wind speed, greatly dissipating the wind’s kinetic energy. This setup also reduces turbulence, eliminates eddies in the incoming wind, and decreases shear stress and pressure on the surface of coal piles, thus reducing dust emission rates. Additionally, dust-blocking walls are placed in non-dominant wind directions to effectively block drifting dust generated during loading and unloading operations using pressure differentials inside and outside the dust-blocking walls, achieving ideal dust-blocking effects. Shangfeng’s wind control and dust suppression walls consist of foundation parts, steel structural support parts, and wind barrier boards. Foundations can be concrete independent foundations or pile foundations. The modular design, factory production, and on-site assembly significantly reduce construction time while ensuring product quality.

3、Application area

Applicable to dust pollution control in open-pit coal yards, ore stockyards, and similar bulk material stockyards. As of now, this technology has been applied in over 300 projects, including at Shenhua, Datang, State Power Investment Corporation, Huadian, China Resources Power, China Datang Corporation, Guohua Electric Power, Guangdong Electric Power, Zhejiang Energy, Shandong Energy, CNPC, Sinopec, Qinhuangdao Port, Qingdao Port, Yantai Port, Rizhao Port, Tianjin Port, Lianyungang Port, Dalian Port, Guangzhou Port, Kemaman Port, Luoyuan, coal terminals, Fangchenggang Port, Qinzhou Port, Handan Iron and Steel, Baotou Iron and Steel, Atalaş Power Plant in Turkey, Kasim Port in Pakistan, Tarbela Power Station in Pakistan, Java Power Plant in Indonesia, Haiyang Power Plant in Vietnam, and Vanino Port in Russia. These projects span over 30 provinces, municipalities, autonomous regions across China and countries along the Belt and Road Initiative, establishing a solid brand reputation. Coverage by media outlets including CCTV News, Xinhua News Agency, People’s Daily Online, and Yangcheng Evening News underscores the technology’s recognition and dissemination.