he fully enclosed project is located within the factory area of Tianji Coal Chemical Group Co., Ltd. in Lucheng City, Shanxi Province. Construction commenced in 2018 and lasted for a period of 4 months. Technologically, it broke through traditional thinking by adopting the recently proposed windbreak wall covering scheme, utilizing the existing windbreak wall for the coal plant’s windbreak wall covering transformation. This scheme provides good ventilation, effectively prevents the formation of indoor dust clouds, reduces dust concentration, improves indoor working environment, lowers the risk of dust explosions, and facilitates the circulation of indoor airflow, as well as the discharge of toxic and harmful gases and smoke. Additionally, it enables effective emergency smoke exhaust in the event of a fire, saving on project costs while meeting current fire inspection and occupational health and environmental requirements.

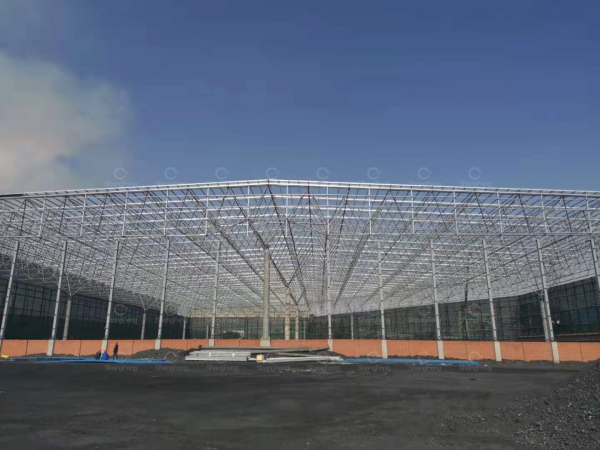

The main structure adopts a truss form, with a length of 160m, a span of 108m, and a height of 19m. The project covers design, supply, construction, and is equipped with lighting, fire protection, dust removal, monitoring, and maintenance systems. The original open-air coal yard in the factory area caused severe coal dust pollution and significant disturbance to nearby residents, resulting in frequent complaints from residents. After the implementation of the fully enclosed coal shed, the air quality around the factory area and the living environment of nearby residents have been greatly improved, gaining recognition from the residents. Additionally, the computerized monitoring of toxic and harmful gases and the spontaneous combustion of coal piles in the coal yard effectively eliminates safety hazards, reduces the workload of the original safety inspection department, and meets the requirements of local environmental protection departments.